erGO!

Fall 2023

Meet erGO! The affordable, portable, ergonomic chair designed for students and commuters seeking a comfortable, supportive chair that can be conveniently carried wherever they go.

My team's aim for this Product and Experimental Design project was to develop an affordable and portable alternative to the standard 'ergonomic chair.' As college students, we typically spend an average of 17 hours per week seated while studying or working, and poor posture can lead to long-term negative effects such as strained necks, back pain, and even heart disease—some of which we already experience.

The current market lacked options that effectively combined portability, affordability, and ergonomics (supporting healthy posture and enhancing comfort). Thus, we embarked on creating one. Here's how our CAD model and the first prototype turned out!

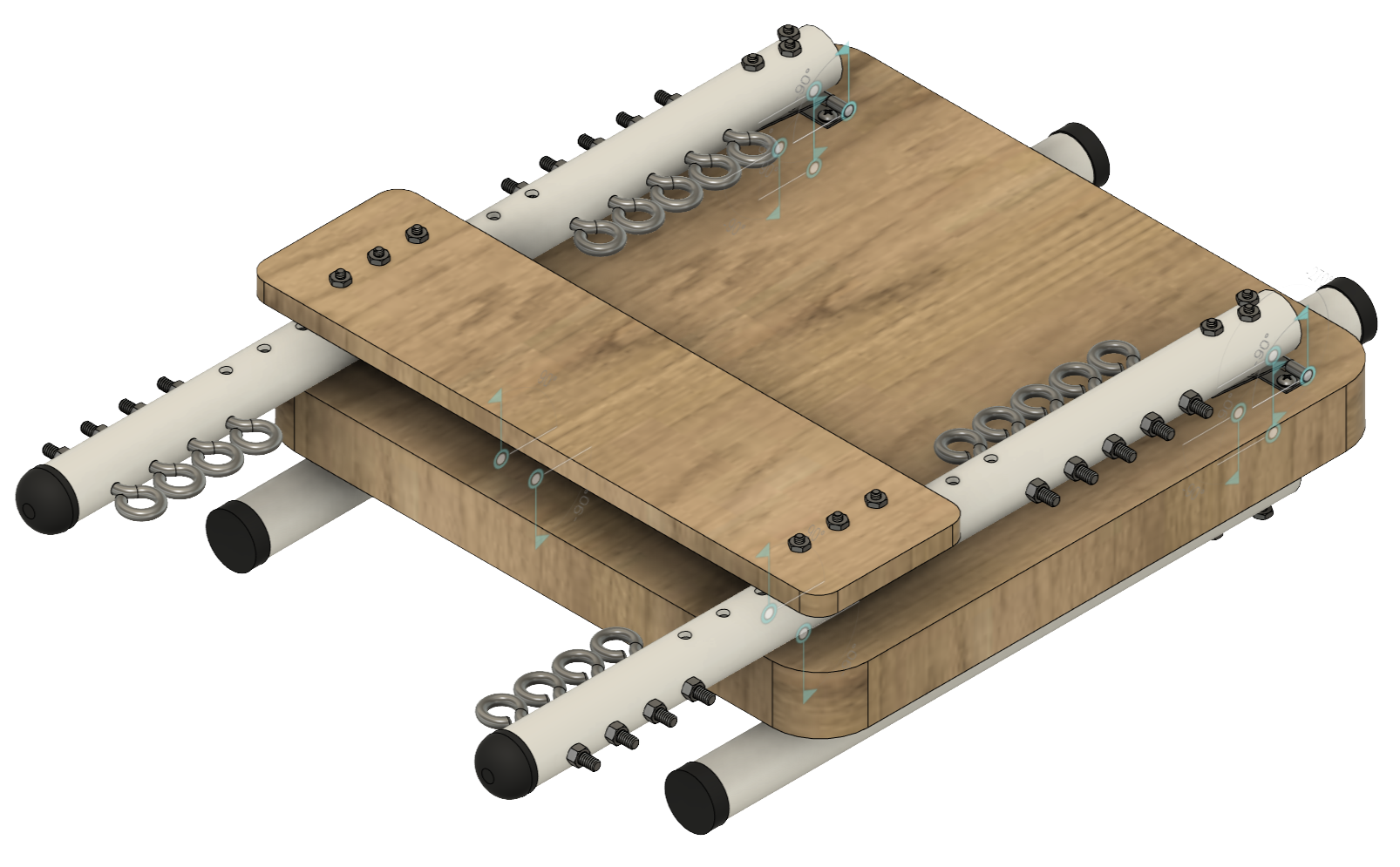

For the construction, we opted for wood, PVC piping, thick 2" foam, 3D-printed parts, and various metal components to assemble our chair. Through mindful material selection, we ensured the chair remained light enough to be easily carried. Recognizing the PVC's compressive strength was more than sufficient to support 200 pounds, we chose to keep it for our final prototype. Moreover, the chair proved exceptionally comfortable and supportive, thanks to the thick foam and proper lumbar support.

As a leg locking mechanism, we designed 3D printable clips in Fusion 360, which we had to prototype many times in order to get them to function properly. We did our best to design the clips so they wouldn't break when the leg was being locked and unlocked, but the brittleness of the filament proved to be quite a challenge. Ideally, these clips would be made out of a metal alloy, but we managed to do pretty well with the resources we had!

Our Final Prototype!

ErGO got quite a facelift with stained wood, spray painted black PVC, black fabric cushion coverings, and a leather handle and strap to hold everything together when in portable mode. Since we hadn't focused on aesthetics for our other prototypes we were quite pleased with how our final prototype turned out.

Ultimately, the total cost for our chair was calculated to be $79 for a single iteration. If we were to produce this chair in bulk, we would likely be able to cut our costs in half to $39 at most, as well as optimize our production process for faster and more efficient chair manufacturing.

We successfully achieved our goal of making a portable, affordable, and ergonomic chair that is comfortable to sit in and easy to carry like a tote bag on your shoulder. If given the opportunity to further develop our design, we would focus on improving the portability and ease of use, as well as decrease the size of the chair. Ideally, the chair would collapse to the size of a dime, but maybe we'll get there in 2100 when nanotech is more commercialized.

Overall, I had a blast collaborating with my engineering peers and doing what I love—designing ergonomic and efficient products, and making things with my hands. I can't wait till my next big assignment! In the meantime, I'll keep having fun with my leathercrafting business and hone my design and craftsmanship skills :)